The Best Kept Secret of High Performing eCommerce Stores

Eco-friendly paperboard mailers, folders, and custom packaging that’s so smart, our competitors sell Conformer products, too. Isn’t it time you buy from the source and save money?

How much postage savings are in store for you?

The Best Kept Secret of High Performing eCommerce Stores

Our packaging is so smart, our clients don’t want you to know about us.

How much postage savings are in store for you?

Efficient Packaging Solutions

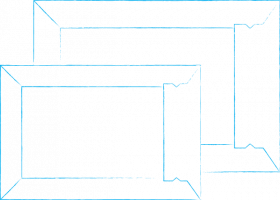

Designed to ship merchandise as USPS Automated Flats

Custom Packages that Delight

Designed to make every unboxing a marketing moment

Big Savings Come

in Small Packages

Typical small merchandise ships as a USPS Lightweight Parcel for $2.80. Conformer packaging ships as a USPS Automated Flat for $1.

Conformer® Envelopes

Cut Your Postage Costs

Our best clients ship merchandise valued between $5 to $30, where pocketing an additional $1.80 yields measurable increases in lifetime value.

Ready to Pack a Punch?

To qualify for our ecommerce packaging solutions, the merchandise you ship must meet the following requirements:

· Under 5/8" thick

· Under 13 ounces

· Under 4" x 6", or flexible

Clothing

Small apparel like accessories, t-shirts, socks, ties, undergarments, and shorts.

Technology

Devices, gadgets, batteries, cables,

and chargers.

Supplements and Health

Vitamins, nutritional supplements,

and energy bars.

Personal Care

Oral hygiene, razors, and grooming.

Beauty Supplies

Makeup and skincare.

Home Supplies

Air fresheners and household

cleaning products.

Clothing

Small apparel like accessories, t-shirts, socks, ties, undergarments, and shorts.

Technology

Devices, gadgets, batteries, cables,

and chargers.

Supplements and Health

Vitamins, nutritional supplements,

and energy bars.

Personal Care

Oral hygiene, razors, and grooming.

Beauty Supplies

Makeup and skincare.

Home Supplies

Air fresheners and household

cleaning products.

Why Use Conformer® Mailers & Custom Packaging?

Ship small consumer goods FAST

Lower subscription eCommerce

program costs

Deliver products safely and with free shipping

Cut costs with our shipping solutions and stay ahead of the competition.

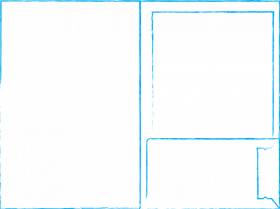

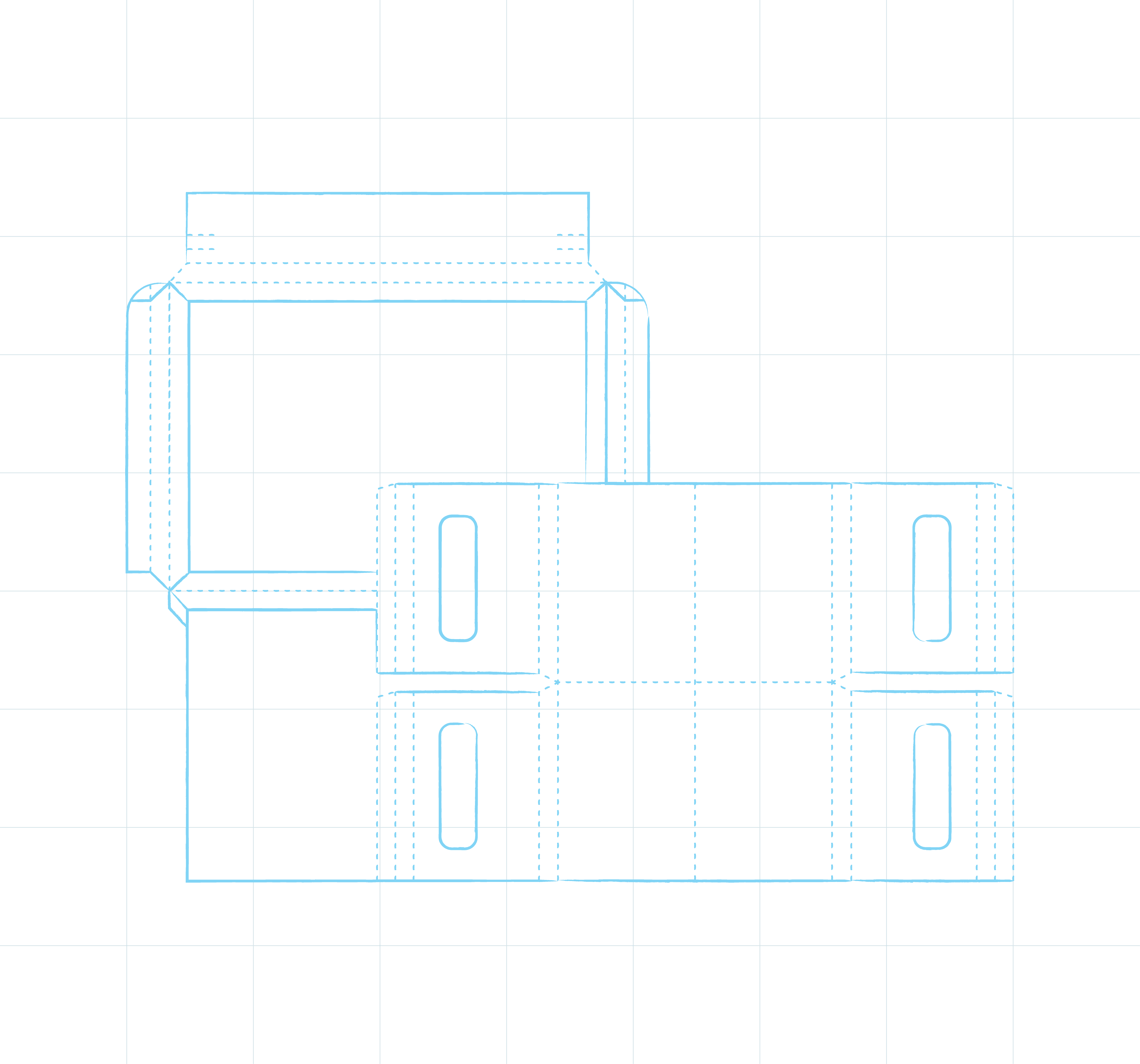

Discover Conformer® Mailers, Folders, and Custom Packaging

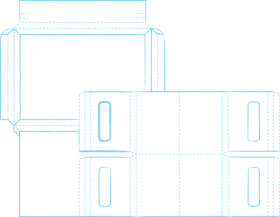

Our patented suite of packaging solutions is purpose-built to maximize USPS processing efficiency. Working with USPS engineers and mailpiece design authorities for nearly 20 years, we have developed packaging capable of running through the USPS’s high-efficiency Flats Sequencing System (FSS), bypassing more costly Parcel mail rates.

How We Work

Design, Test, Approve, and Deliver

1. Develop custom packaging concept utilizing our catalog of patented solutions

2. Produce CAD sample for testing

3. Secure USPS approval for Automation Flats rates

4. Introduce clients to fulfillment partners and mail consolidators to maximize savings

5. Manufacture custom packaging

1. Develop custom packaging concept utilizing our catalog of patented solutions

2. Produce CAD sample for testing

3. Secure USPS approval for Automation Flats rates

4. Introduce clients to fulfillment partners and mail consolidators to maximize savings

5. Manufacture custom packaging

Three Conformer® Packaging Solutions to Match Your Needs