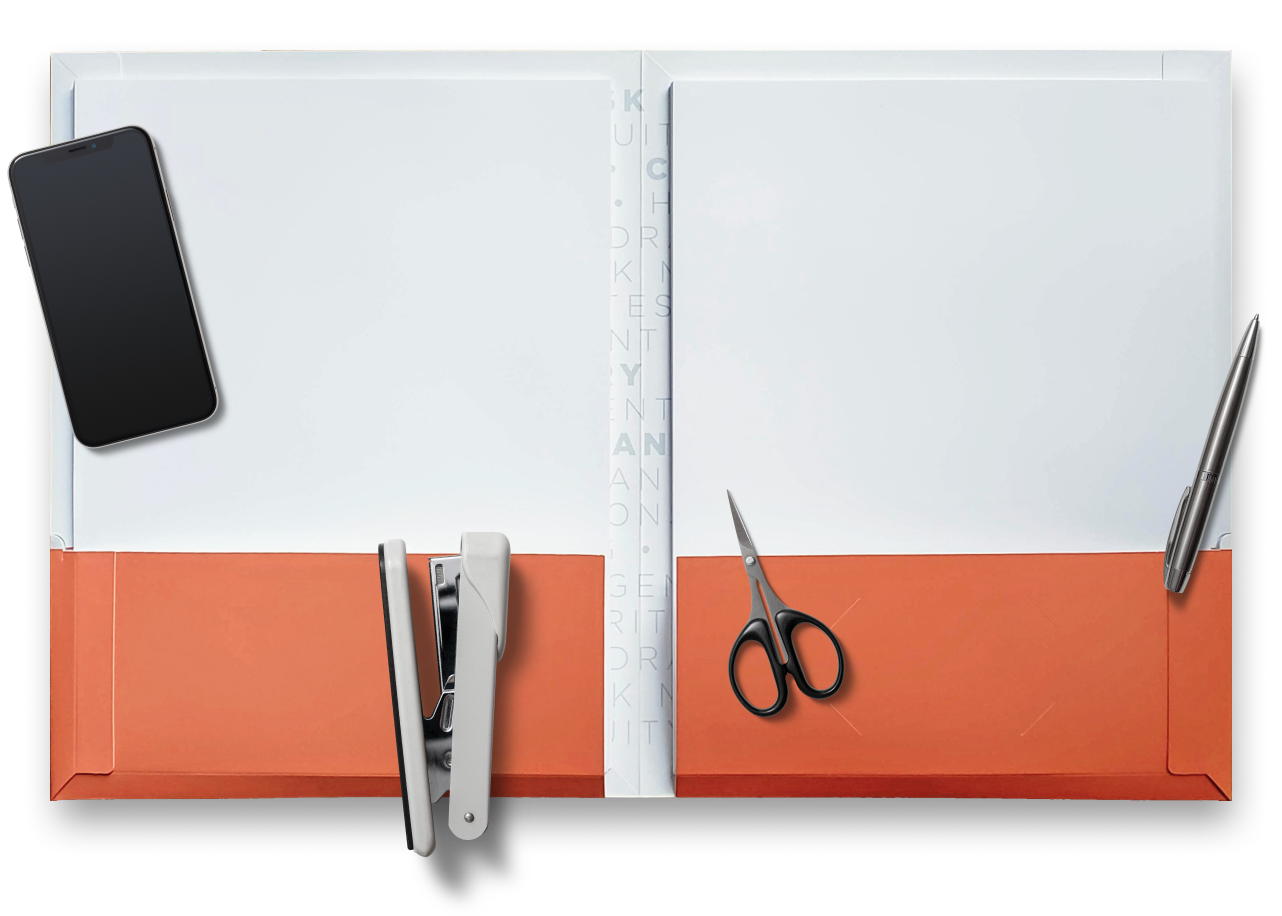

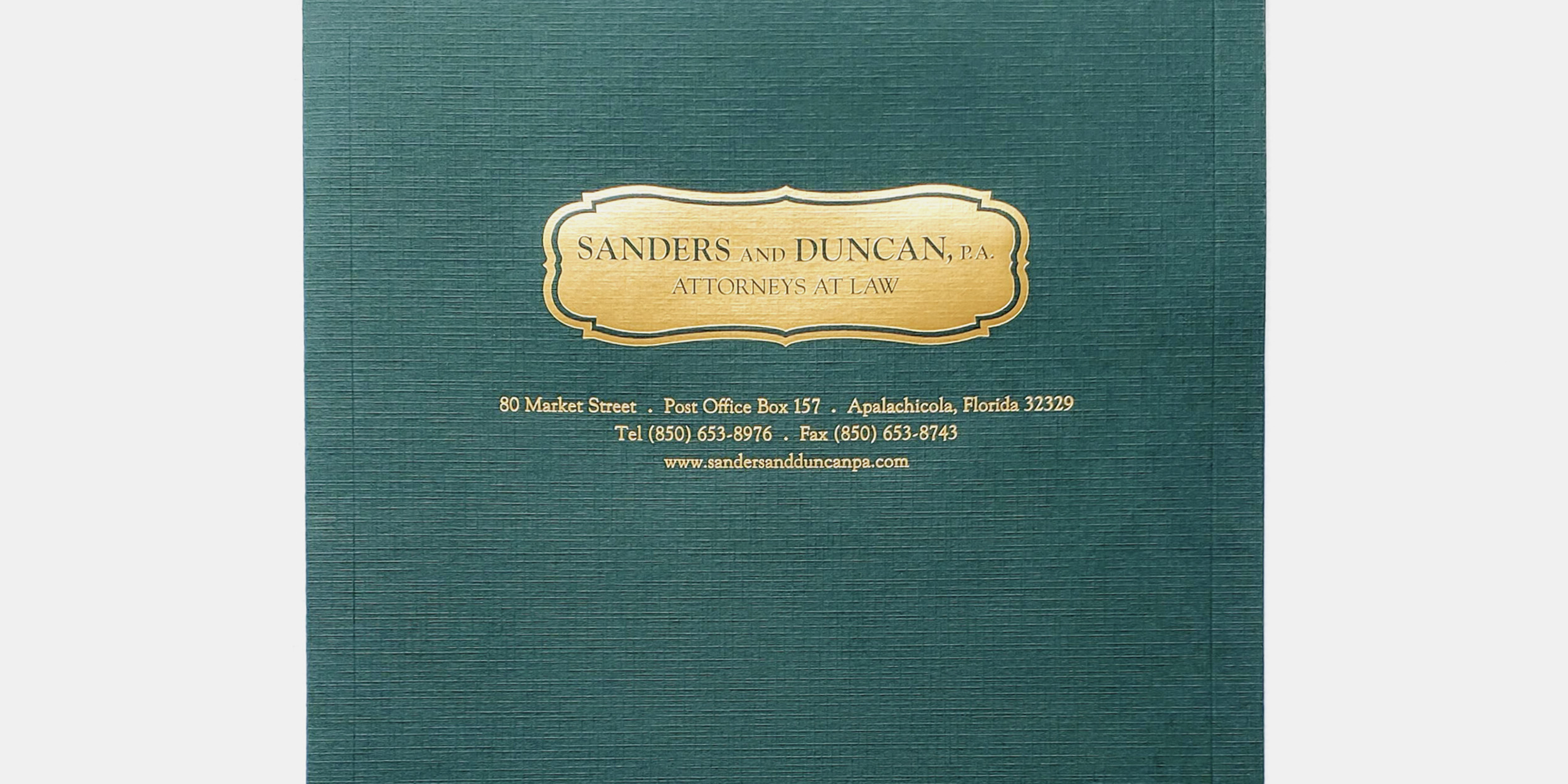

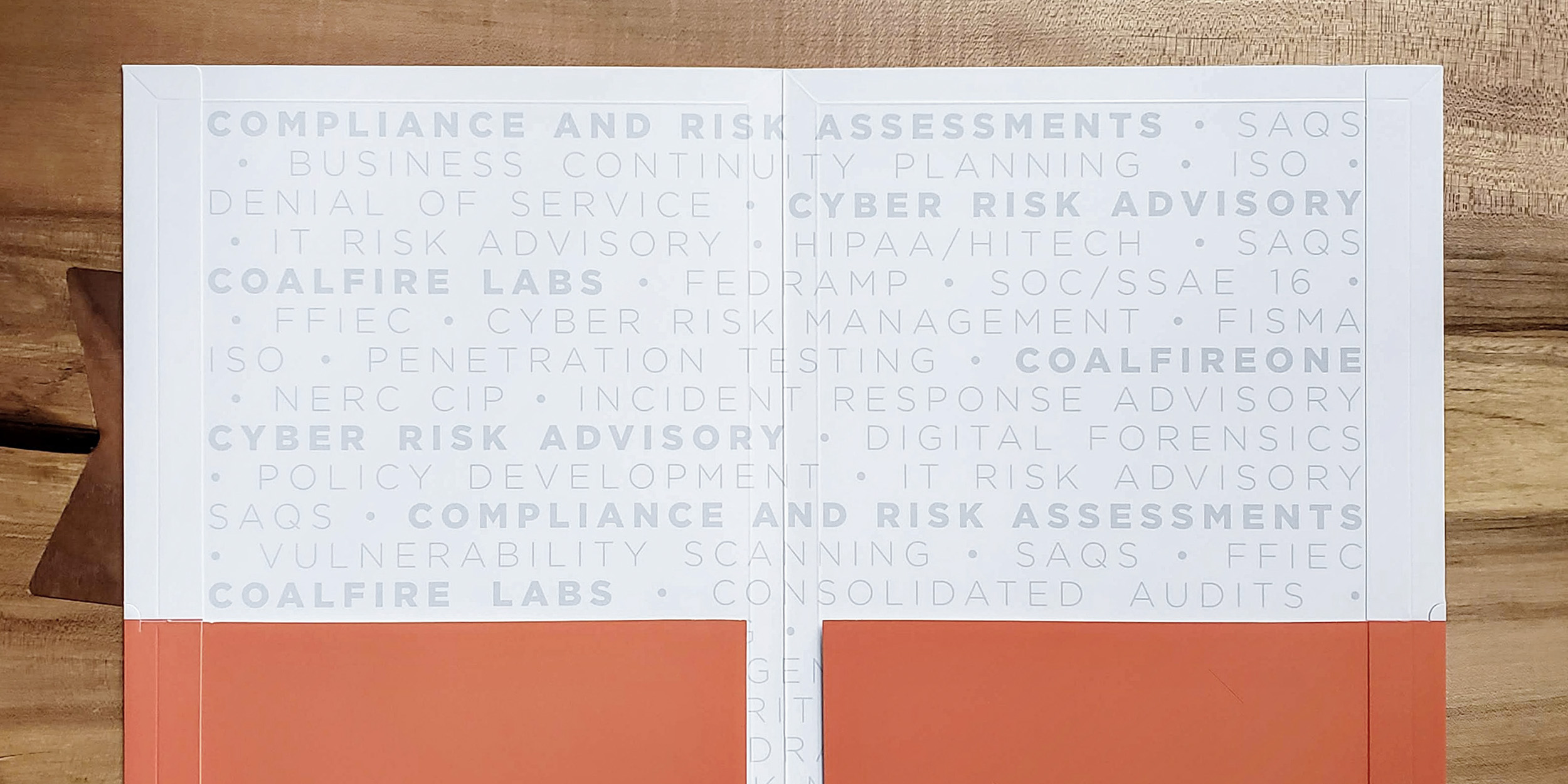

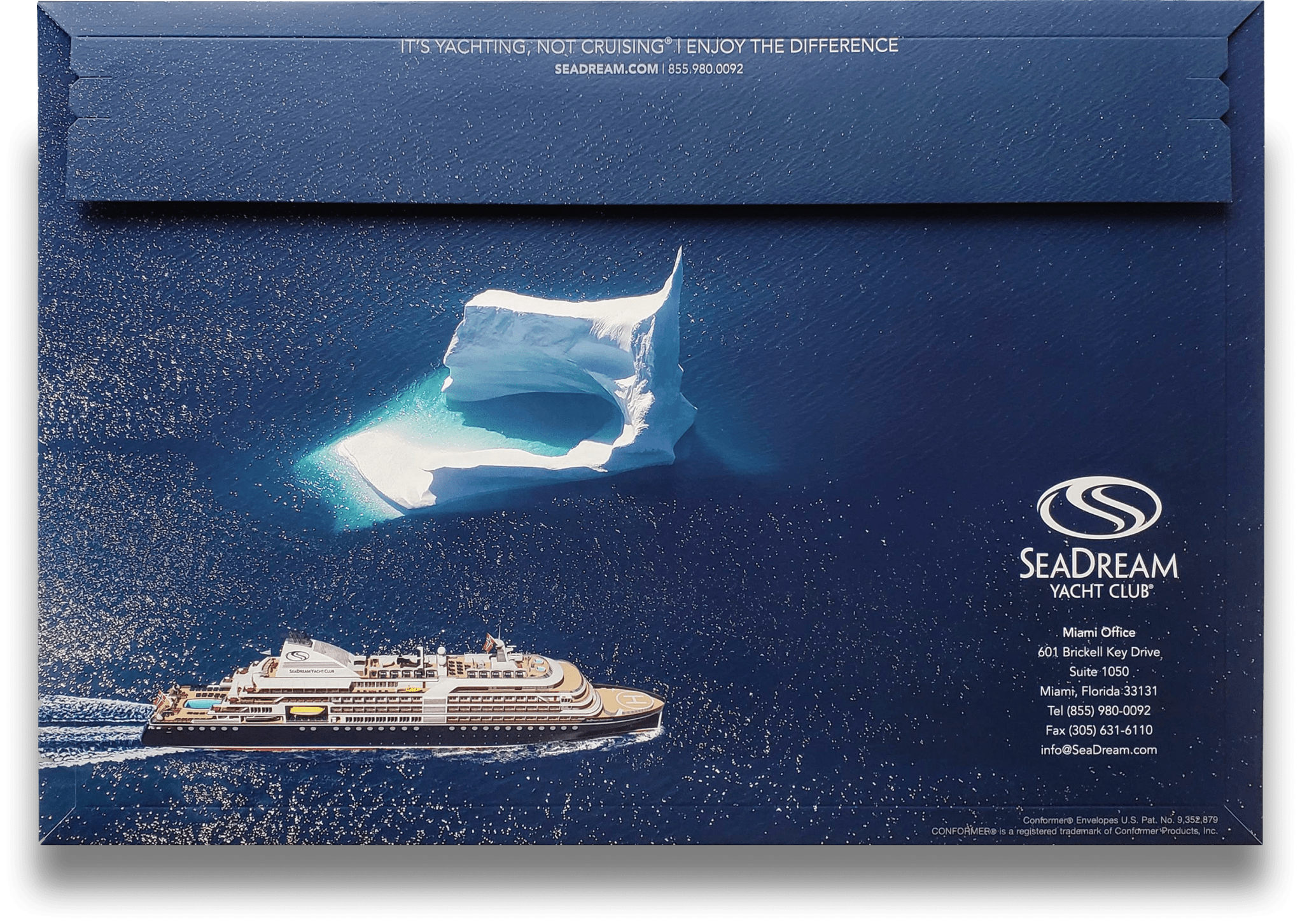

Presentation folders and mailers designed to look and work great every time.

Already a customer? Log in.

Cancel your order for a full refund, up until you approve your proof.

If we didn't do it right, we'll make it right. Period.

Pick your paperboard

Pick foil stamping or ink, and customize layout

Upload artwork or use pre-set art formats

Add to cart or complete your purchase

You will receive a PDF proof within 1 to 2 business days of submitting an order.

Sign up for Conformer Folders emails and get 10% off your first order, plus stay updated on special offers, printing tips & more!

* New customers only. Code will be emailed to the address you enter.

44 South Bayles Ave., Ste. 205

Port Washington, NY 11050

Copyright © 2020 Conformer Products, Inc.. All rights reserved. CONFORMER® is a registered trademark of Conformer Products, Inc.

U.S. Pat. Nos.: 8,162,204 : 8,215,537 : 8,684,259 : 8,215,619 : 8,215,345 : 9,352,879. Canadian Pat. Nos. 2,418,571: 2,554,473 : 2,641,639. Other Patents Pending.

|

Uploaded

Failed

|

|